Blend Fuel Constraint ID Column

Column Type = Text

Use this column to enforce fuel blending for a resource (or multiple resources referring to a common fuel). To apply fuel blending between two fuels, provide a reference ID of a fuel constraint.

This column can only be used for the constraint types Fuel Min Blend and Fuel Max Blend and can only contain a single Set ID of the constraint type Fuel Max or Fuel Min.

How to apply Annual or Monthly fuel blending constraints?

Case 1: For a resource, the ratio of secondary fuel (Fuel 2) to total fuel usage (Fuel 1 + Fuel 2) >= 0.2, annually.

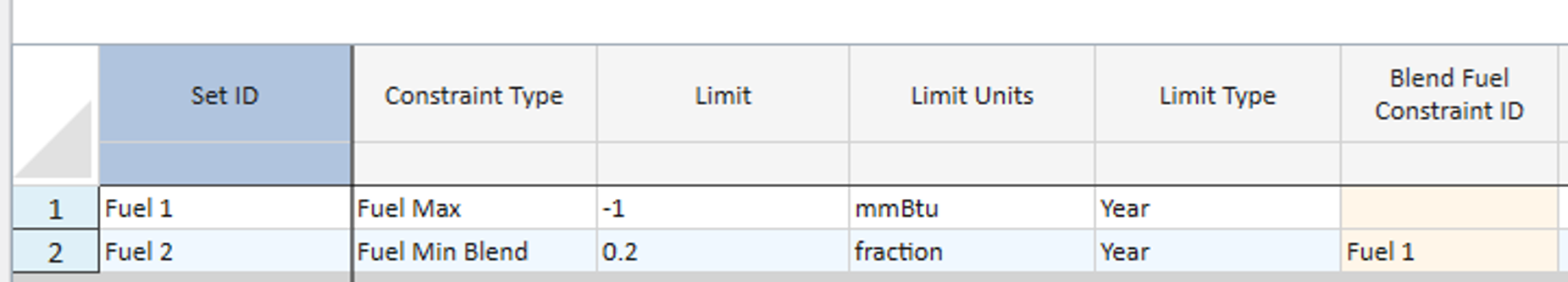

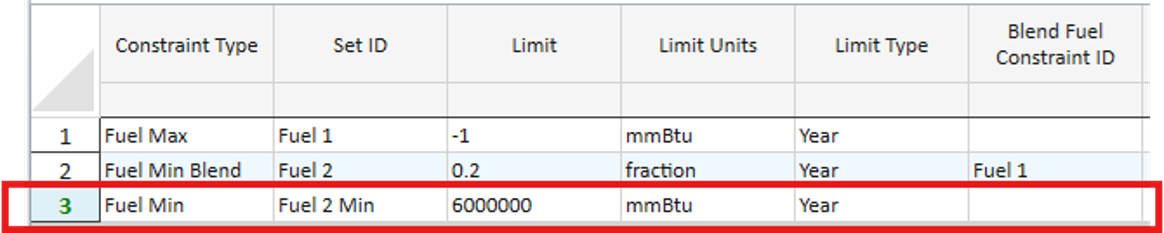

In Constraint Table:

- Create two constraints with Set IDs - one for Fuel 1 and the other for Fuel 2.

- Set the constraint type of Fuel 2 as Fuel Min Blend, with Limit of 0.2 and units as fraction.

- Set the constraint type of Fuel 1 as Fuel Max, with Limit of -1 (Default is -1 if empty, or can be specified in mmBTU) and units as mmBTU.

- Reference the Fuel Min Blend constraint (Fuel 2) to Fuel 1 using the Blend Fuel Constraint ID in the Constraint table. This column should contain Set ID of Fuel 1.

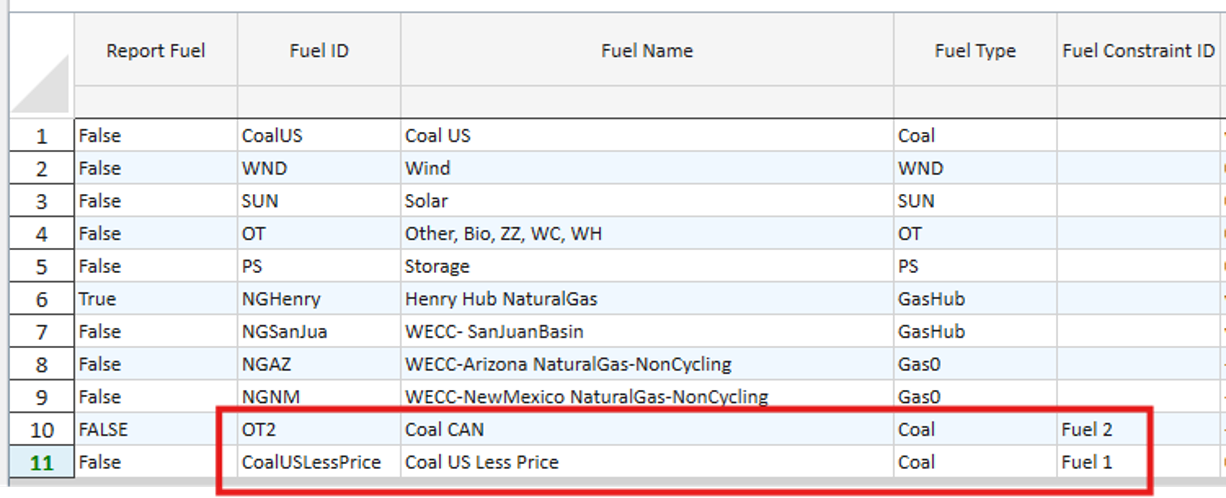

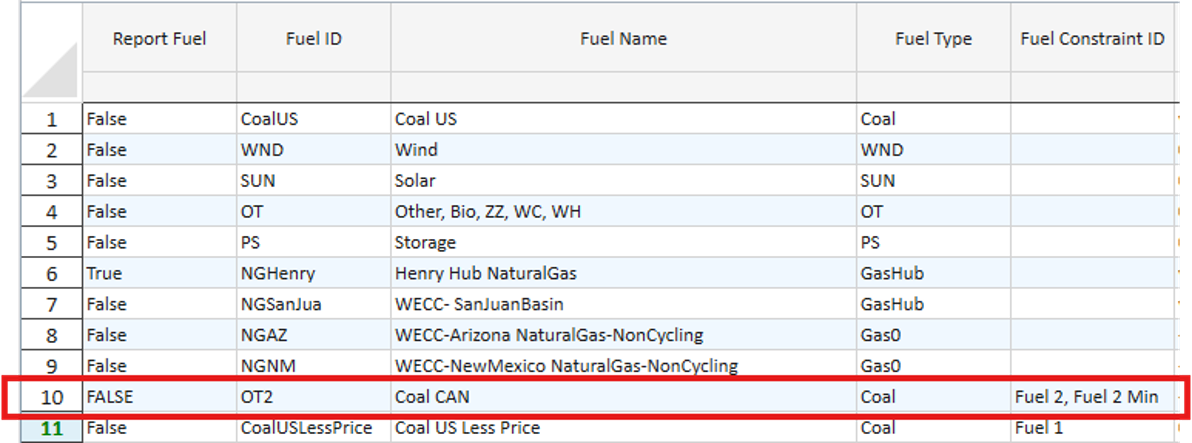

In Fuel Table:

- Refer to the Set IDs – Fuel 1 and Fuel 2 in the Fuel Constraint ID column of the Fuel table. Here, CoalUSLessPrice is the primary fuel, and OT2 is the secondary fuel.

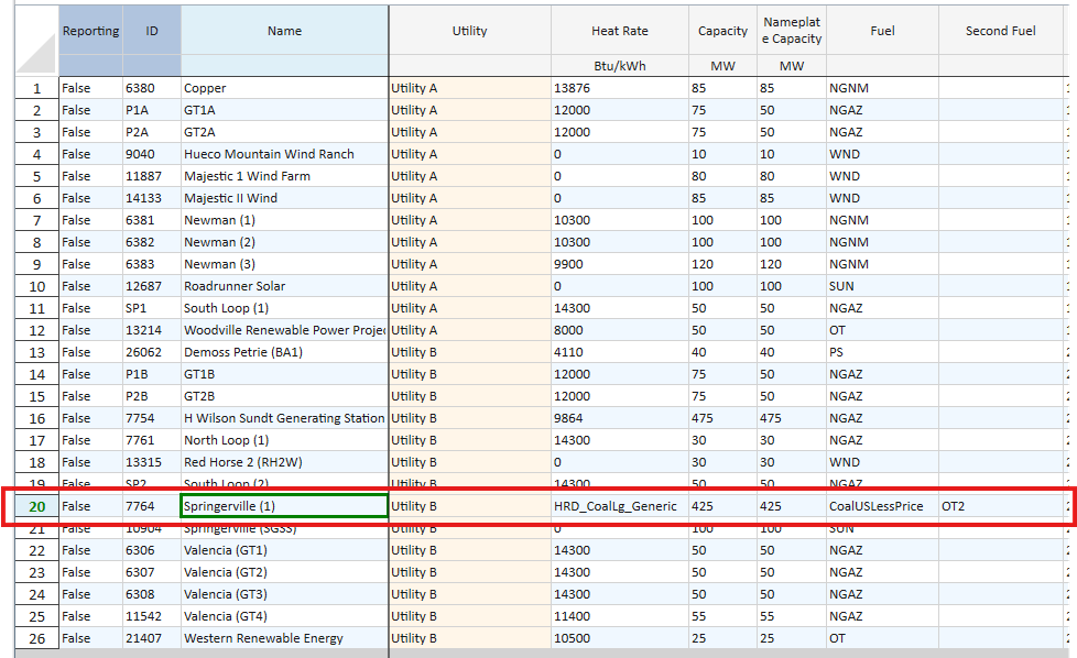

In Resource Table:

- Here, Resource ID 7764 – Springerville (1) is the resource with two fuels – CoalUsLessPrice as the primary fuel and OT2 as the secondary fuel.

![]() NOTE:

NOTE:

- To apply the limits on the monthly level, select the Limit type for both constraints as Month.

- If using a Fuel Min Blend Constraint, the Blend Fuel Constraint ID should be non-empty and must contain the Set ID of a Fuel Max type constraint. Thus, the Fuel Min Blend constraint can only reference the Fuel Max type constraint.

- If Fuel 2 in Case 1 has a min limit of 6000000 mmBTU in addition to Fuel Min Blend, a new Fuel Min constraint must be created in the Constraint table as shown below:

The Set ID - Fuel 2 Min must then be referenced in the Fuel Constraint ID column of the Fuel table for the OT2, as shown below.

Case 2: For a resource, the ratio of primary fuel (Fuel 1) to total fuel usage (Fuel 1 + Fuel 2) <=0.8, annually.

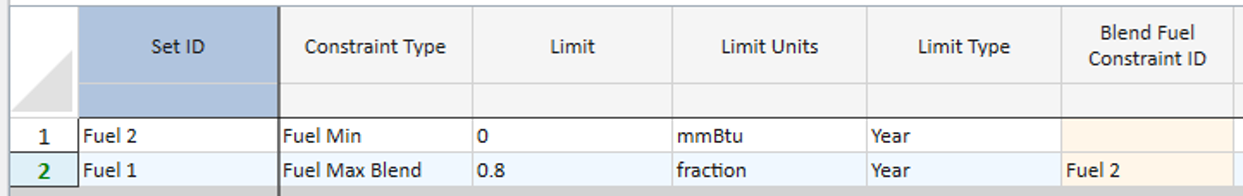

In Constraint Table:

- Create two constraints with Set IDs - one for Fuel 1 and the other for Fuel 2.

- Set the constraint type of Fuel 1 as Fuel Max Blend with Limit of 0,8 and units as fraction.

- Set the constraint type of Fuel2 as Fuel Min, with Limit of 0 (Default is 0 if empty, or it can be specified in mmBTU) and units as mmBTU.

- Provide a reference from the Fuel Max Blend constraint (Fuel1) to Fuel 2 via the Blend Fuel Constraint ID column. This column should contain Set ID of Fuel 2.

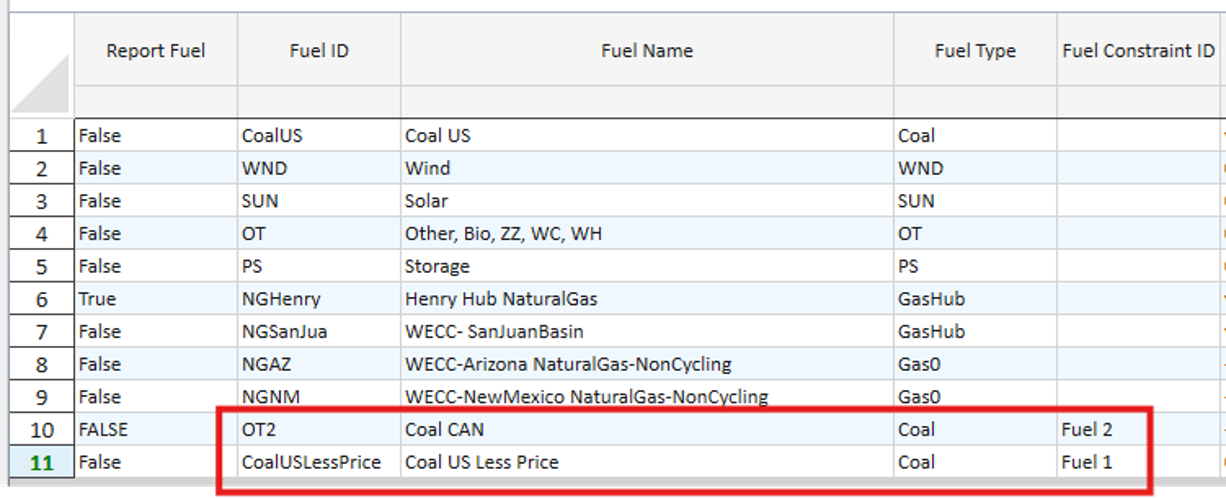

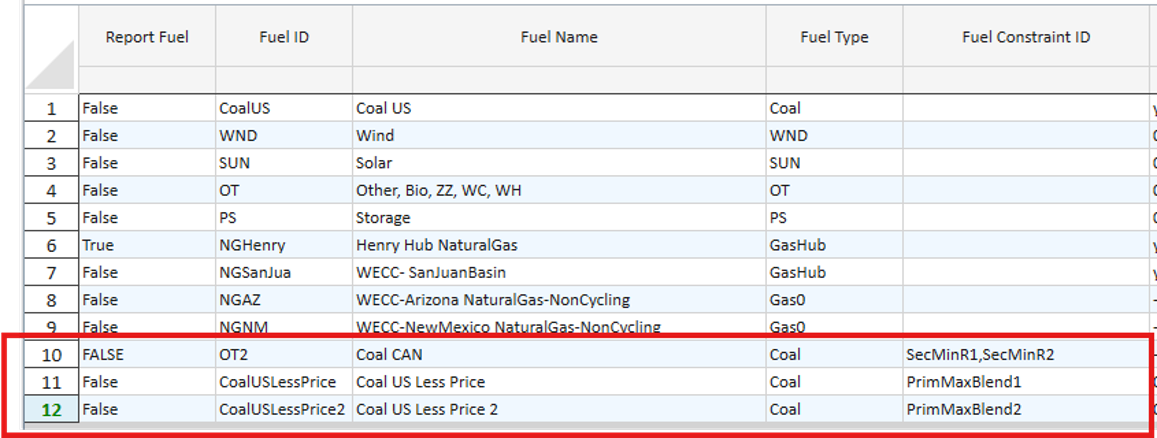

In Fuel Table:

- Refer the Set IDs - Fuel 1 and Fuel2 in the Fuel Constraint ID column of the Fuel table. CoalUSLessPrice is the primary fuel, and OT2 is the secondary fuel.

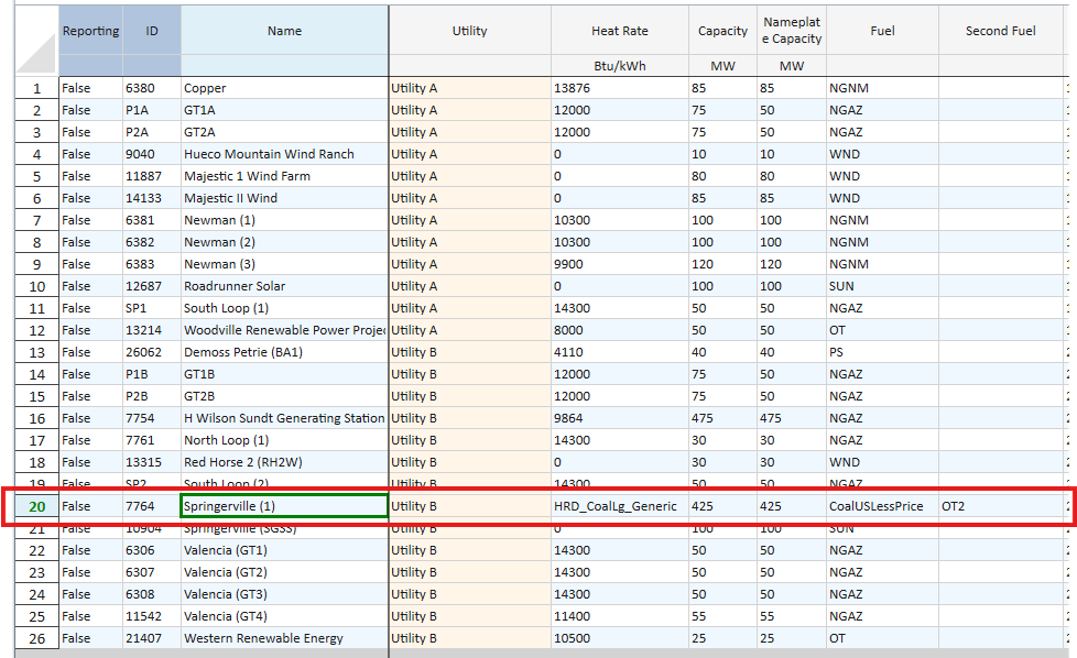

In Resource Table:

- Here, Resource ID 7764 – Springerville (1) is the resource with two fuels – CoalUsLessPrice as the primary fuel, and OT2 as the secondary Fuel.

![]() NOTE:

NOTE:

- If using a Fuel Max Blend constraint, the Blend Fuel Constraint ID should be non-empty, and must contain the Set ID of a Fuel Min type constraint. Thus, the Fuel Max Blend constraint can only reference the Fuel Min type constraint.

- If Fuel 1 in Case 2 has a max limit in addition to Fuel Max Blend, a new Fuel Max constraint must be created in the Constraint table. The Set ID for this new Fuel Max must be referenced in Fuel Constraint ID column of the Fuel table for CoalUSLessPrice.

Case 3: For a resource:

- The ratio of primary fuel (CoalUSLessPrice) to total fuel usage <= 0.7, annually.

- The ratio of secondary fuel (OT2) to total fuel usage >= 0.1, annually.

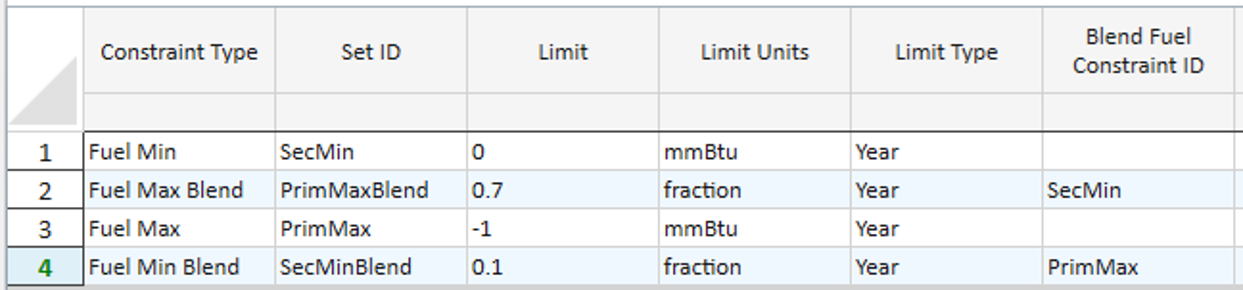

In Constraint Table:

- Create two constraints with Set IDs – PrimMaxBlend (with limit 0.7) and SecMin (with default limit 0 or any other limit in mmBTU) for the first blending constraint. Provide a reference of SecMin to PrimMaxBlend.

- Create two constraints with SetIDs – SecMinBlend (with limit 0.1) and PrimMax (with default limit -1 or any other limit in mmBTU) for the second blending constraint. Provide a reference of PrimMax to SecMinBlend.

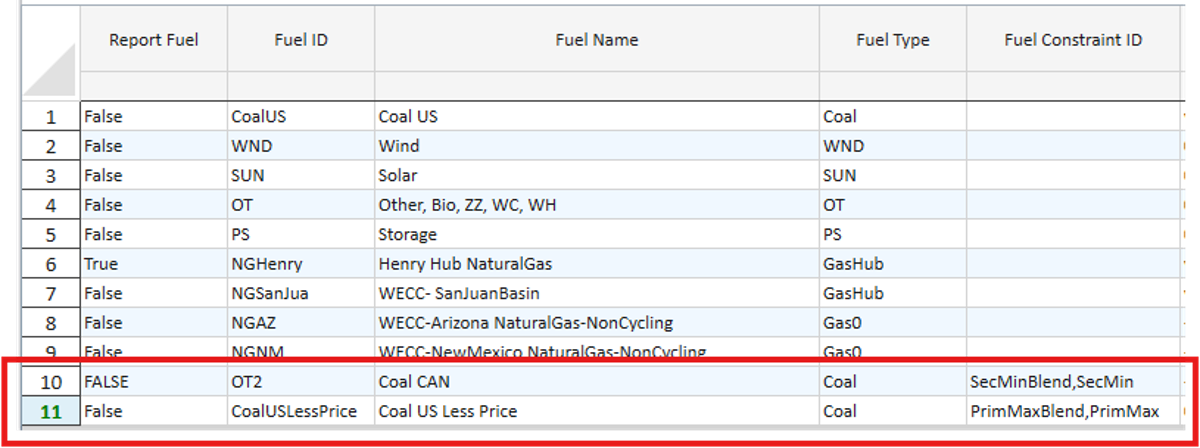

In Fuel Table:

- Refer the Set IDs – PrimMaxBlend and PrimMax in the Fuel Constraint ID column of the Fuel table for the primary fuel - CoalUSLessPrice.

- Refer the Set IDs – SecMinBlend and SecMin in the Fuel Constraint ID column of the Fuel table for the secondary fuel – OT2.

- Here, Resource ID 7764 – Springerville (1) is the resource with two fuels – CoalUsLessPrice as the primary fuel and OT2 as the secondary Fuel (The Resource table is the same as in Case 1 and Case 2).

Case 4: For a resource:

- 0.1 <= The ratio of primary fuel (CoalUSLessPrice) to total fuel usage <= 0.7, annually.

In Constraint Table:

- Create two constraints with Set IDs – PrimMaxBlend (with limit 0.7) and SecMin (with default limit 0 or any other limit > 0) for implementing <= 0.7 constraint. Provide a reference of SecMin to PrimMaxBlend.

- Create two constraints with SetIDs – PrimMinBlend (with limit 0.1) and SecMax (with default limit -1 or any other limit > 0) for implementing >= 0.1 constraint. Provide a reference of SecMax to PrimMinBlend.

In Fuel Table:

- Refer the Set ID’s – PrimMaxBlend and PrimMinBlend in the Fuel Constraint ID column of the fuel table for the primary fuel - CoalUSLessPrice.

- Refer the Set ID’s – SecMin and SecMax in the Fuel Constraint ID column of the fuel table for the secondary fuel – OT2.

- Here, Resource ID 7764 – Springerville (1) is the resource with two fuels – CoalUsLessPrice as the primary fuel and OT2 as the secondary Fuel (The Resource table is the same as in Case 1 and Case 2).

Additional considerations while applying fuel blending constraints

It is possible to also have multiple resources with same primary and secondary fuel or different combinations of the two fuels, with some fuels in common. In such a case, each fuel blending constraint must appear in a pair in the constraint table (i.e., A Fuel Max Blend must have a Fuel Min, and a Fuel Min Blend must have a Fuel Max). Below is a case to demonstrate the types of input that can/cannot be provided via the constraint table.

Case 5: Two resources have different primary fuels but common secondary fuels.

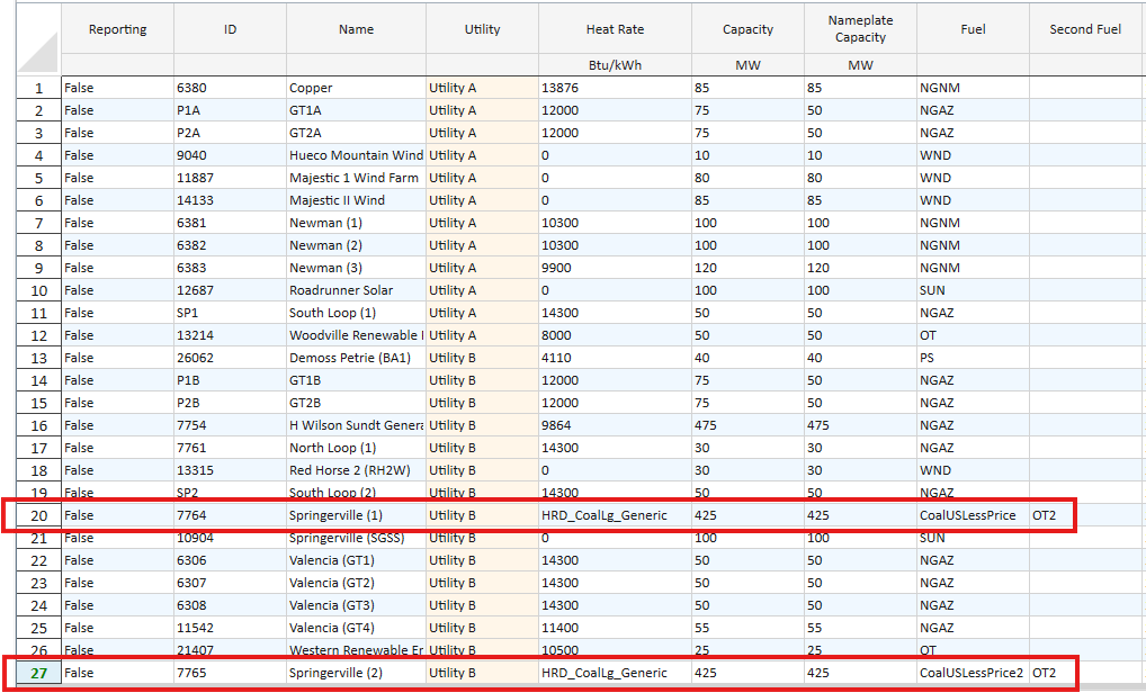

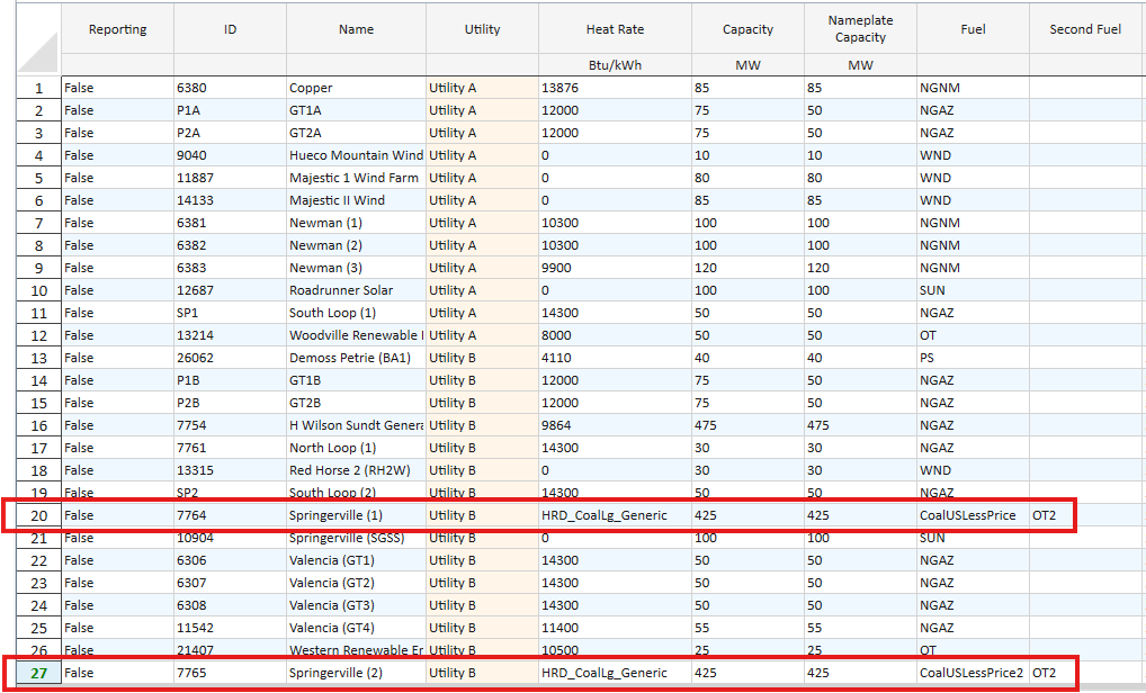

In Resource Table:

- Here, Springerville(1) has a primary fuel – CoalUsLessPrice, and secondary fuel – OT2.

- Springerville(2) has a primary fuel – CoalUsLessPrice2, and secondary fuel – OT2.

- For Springerville(1), the ratio of primary fuel usage to total fuel usage must be <= 0.7, annually.

- For Springerville(2), the ratio of primary fuel usage to total fuel usage must be <= 0.5, annually.

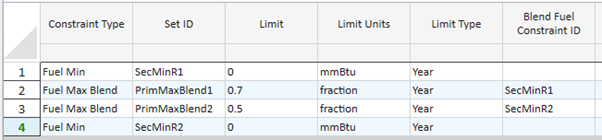

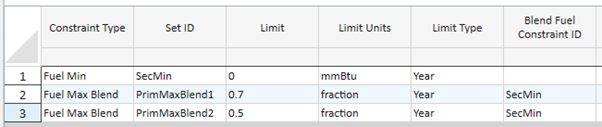

In Constraint Table:

- Create two constraints with Set IDs – PrimMaxBlend1(with limit 0.7) and SecMinR1(with default limit 0 or any other limit > 0) for implementing <= 0.7 constraint. Provide a reference of SecMinR1 to PrimMaxBlend1.

- Create two constraints with Set IDs – PrimMaxBlend2 (with limit 0.5) and SecMinR2 (with default limit 0 or any other limit > 0) for implementing <= 0.5 constraint. Provide a reference of SecMinR2 to PrimMaxBlend2.

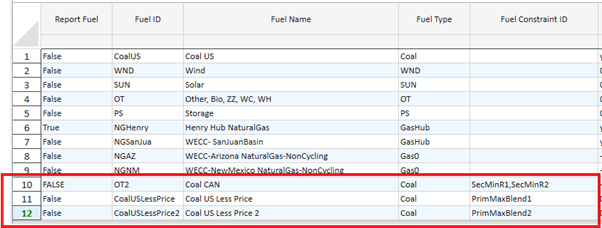

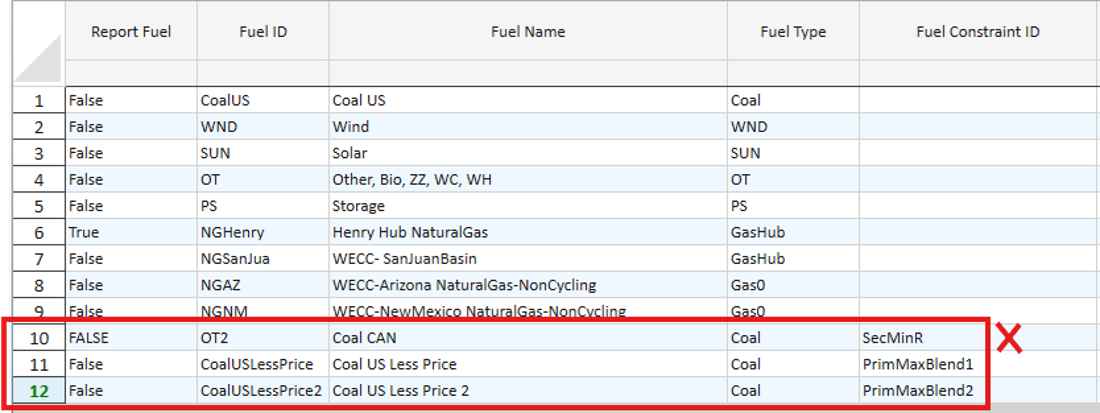

In Fuel Table:

- Refer the Set IDs – SecMinR1, SecMinR2 in the Fuel Constraint ID column for the secondary fuel – OT2.

- Refer the Set ID – PrimMaxBlend1 in the Fuel Constraint ID column for the primary fuel – CoalUSLessPrice.

- Refer the Set ID – PrimMaxBlend2 in the Fuel Constraint ID column for the primary fuel – CoalUSLessPrice2.

![]() NOTE:

NOTE:

- Since secondary fuel OT2 is common for both the resources – Springerville(1) and Springerville(2), it might be tempting to write the constraints in the manner shown below in the Constraint table:

In Constraint Table:

You may then want to refer to the Set ID—SecMin to Fuel Constraint ID of the secondary fuel OT2 in the fuel table (as shown below).

This is not allowed. Each fuel blending constraint (in this example - two Fuel Max Blend constraints) must have an associated fuel type constraint (which are Fuel Min constraints for both in this case). Thus, each Blend Fuel Constraint ID must be unique.

![]() Blend Fuel Constraint ID Column

Blend Fuel Constraint ID Column